Open Works is the largest nonprofit makerspace in the country, and it is located in central Baltimore. Their space serves as an environment where anyone can build nearly anything they want with shared access to tools.

Open Works is the largest nonprofit makerspace in the country, and it is located in central Baltimore. Their space serves as an environment where anyone can build nearly anything they want with shared access to tools.

Open Works brings together people who want to learn new skills–from 3D printing to laser cutting, from woodworking to textiles, and more–as well as creative professionals of all stripes. They also offer classes, studio rentals, and community workshops. In all they do, they promote trust and economic growth.

To prevent the spread of COVID-19, the state of Maryland issued the closing of businesses. Part-time employees at Open Works were laid off, and at the same time, social media was flooded with posts about healthcare workers facing a large shortage of personal protective equipment (PPE). Will Holman, the Executive Director of Open Works and architect by training, saw this need and worked with remaining staff to plan out how they could get involved.

To prevent the spread of COVID-19, the state of Maryland issued the closing of businesses. Part-time employees at Open Works were laid off, and at the same time, social media was flooded with posts about healthcare workers facing a large shortage of personal protective equipment (PPE). Will Holman, the Executive Director of Open Works and architect by training, saw this need and worked with remaining staff to plan out how they could get involved.

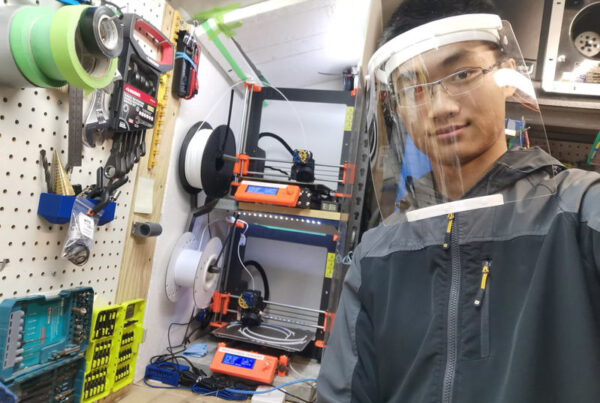

With twenty 3D printers and four laser cutters at their facility, Holman explored how to design a face shield. Working with local healthcare experts, they were able to make their first shield. One issue they ran into was the lack of manpower and capacity to make face shields in bulk. Holman shares that they are running on at least 30 hours a week with between 5-8 people per shift. Leveraging the power of social media once more, Open Works advertised to those who had access to 3D printers. The support poured in. Libraries, schools, homes, and military bases in Maryland stepped forward to help. They activated a network of 350 home printers and partnered with Innovation Works and We the Builders to assist in the distribution and supply chain. Open Works was now mobilizing makers under the “Makers Unite” initiative to 3D print face shields from locations all around Maryland.

Here is how the system works:

- 3D print parts from a remote location

- Drop the parts off at Open Works

- Staff disinfects parts at Open Works

- Laser cut shields

- Cut elastic bands with hot cutter

- Assemble parts together

- Check finished products for defects

- Clean each face shield with compressed air

- Pack each face shield in a bag

- Ship face shields to health facilities in need

As of May 13, 2020, 16,575 face shields have been distributed through Makers Unite. The face shields are available to purchase at www.mdmakersunite.org.

Makers Unite is working with Get Us PPE, a nationally recognized platform, to distribute face shields regionally. Open Works and the Makers Unite initiative is the first recipient of the Get Us PPE Maker Grant, a funding opportunity to support the production of PPE by makers to fill otherwise unmet PPE needs. Nation of Makers, the national association for maker organizations, has supported this effort and similar efforts throughout the United States. With a growing need for protective equipment to help our frontline health workers stay safe, makers and businesses are not standing by and watching. They are getting involved in the effort and creating life-saving PPE.

Makers Unite is working with Get Us PPE, a nationally recognized platform, to distribute face shields regionally. Open Works and the Makers Unite initiative is the first recipient of the Get Us PPE Maker Grant, a funding opportunity to support the production of PPE by makers to fill otherwise unmet PPE needs. Nation of Makers, the national association for maker organizations, has supported this effort and similar efforts throughout the United States. With a growing need for protective equipment to help our frontline health workers stay safe, makers and businesses are not standing by and watching. They are getting involved in the effort and creating life-saving PPE.

By Zayba Syed, a blog contributor at GetUsPPE.org and Virginia Tech graduate working to pursue a Masters of Public Health-Physician Assistant (MPH-PA) dual degree.