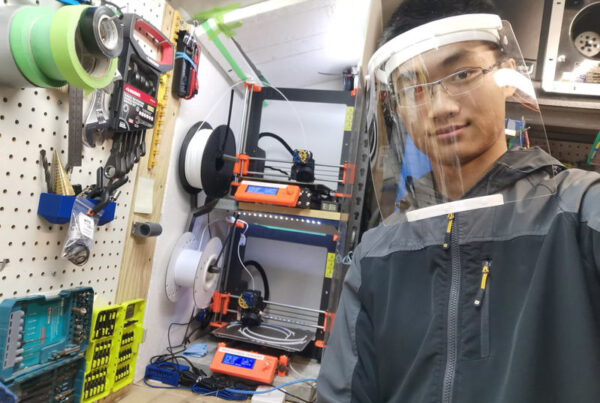

One of the largest and most established makerspaces in the country, NOVA Labs is gaining attention as an innovative personal protective equipment (PPE) supplier. Located in Reston, VA, a town west of Washington, D.C., NOVA Labs is helping its community fight COVID-19 by creating in-demand PPE using creative techniques like 3D printing.

One of the largest and most established makerspaces in the country, NOVA Labs is gaining attention as an innovative personal protective equipment (PPE) supplier. Located in Reston, VA, a town west of Washington, D.C., NOVA Labs is helping its community fight COVID-19 by creating in-demand PPE using creative techniques like 3D printing.

Local Firefighters Ask NOVA Labs for Help Producing Life-Saving PPE Equipment

One of the ways that NOVA Labs has helped the community is by supplying innovative devices to firefighters likely to come in contact with COVID-19 during their service. The collaboration between NOVA Labs and the D.C. Fire Department has been covered in the media, including in the Washington Post.

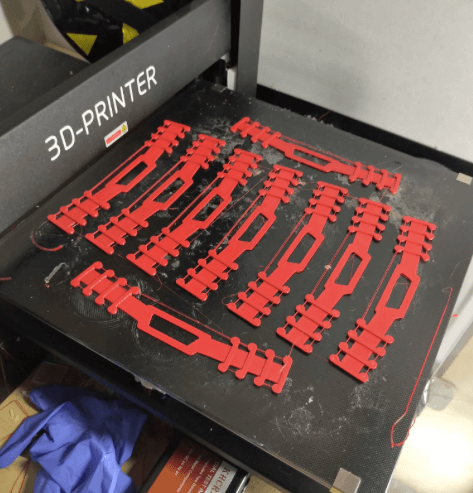

To protect first responders from exposure to COVID-19, the D.C. Fire Department sought a way to adapt and attach filters to Continuous Positive Airway Pressure (CPAP) machines that are used to help patients breathe in ambulances. The adapter filters the air protecting the first responders administering aid.

The fire department got in contact with NOVA Labs to ask for help producing a special adapter. NOVA Labs responded to the call by printing and delivering this critical adapter in record time. Within hours, NOVA Labs presented a prototype, and within three days, they delivered 1,000 adapters to the local Emergency Medical Services (EMS).

The adapter they developed allows for CPAP machines to be used to safely treat patients with COVID-19. Although this part is usually commercially available, global supply shortages made it necessary for the community to collaborate and find a solution. Through the NOVA Labs PPE Challenge, the makerspace ultimately delivered more than 1,700 adapters.

Collaboration, Innovation, Dedication : NOVA Labs and the Medical Community

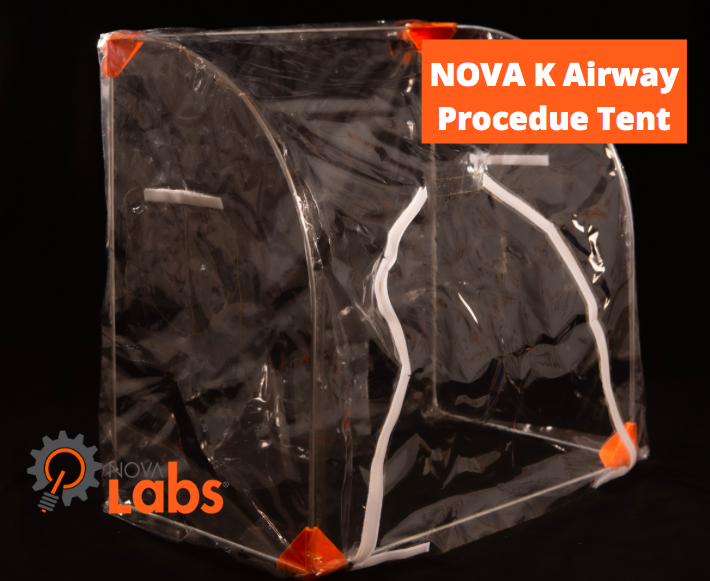

Another example that showcases NOVA Labs’ engineering ingenuity for solving community problems is their novel take on the NOVA-K Airway Procedure Tent.

Their design significantly improves protection tent prototypes which were initially developed as an additional layer of protection for healthcare workers’ safety. Since COVID-19 is a respiratory disease, workers performing advanced emergency airway management on COVID-19 patients are at greater risk without the additional barrier during procedures.

NOVA Labs engineers worked with emergency medical clinicians to design an improved procedure tent. This design features corner covers for versatility across many bed shapes. The tent features bilateral side ports, allowing for the passage of equipment without lifting the tent. The neck flaps reduce any air movement that could affect additional staff.

The Nova-K APT design is a vital piece of PPE that enables emergency personnel to better care for COVID-19 patients without compromising their own personal safety.

What Personal Protective Equipment is NOVA Labs Producing?

NOVA Labs is a community of makers who operate as a collective, providing accessibility to machinery and tools for the local community. In response to COVID-19, they have used the same spirit of innovative design and manufacturing ingenuity to answer the call for healthcare workers in desperate need of PPE. Although it is the first time NOVA Labs makerspace got involved in such an effort for the health industry, their efforts are already making a crucial difference.

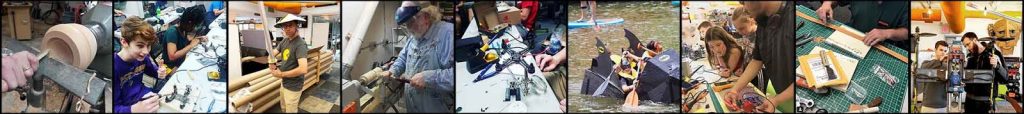

NOVA Labs, previously focused on giving its community access to tools for projects in the areas of robotics, electronics, fiber arts, woodworking, metal working, blacksmithing, and drone building, quickly switched gears to produce quality supplies for the healthcare community.

All Personal Protective Equipment that NOVA Labs designs and manufactures are being donated directly to frontline responders battling COVID-19, drawing on the time, skills, and materials provided by volunteer makers. NOVA Labs is currently producing a wide variety of PPE and intends to continue as needs arise. Their current repertoire of PPE consists of:

To produce these items, NOVA Labs collaborates with a variety of local manufacturers and groups who are also committed to creating and donating PPE to hospitals and healthcare workers in need. Many of these efforts are worthy of highlighting because of their outstanding work and dedication in giving healthcare workers the protection they need to keep saving lives.

As soon as the media started covering the impending PPE shortage, the makers at NOVA Labs got to work. With the physical Nova Labs facility closed, the team resorted to trying to cut shield material by hand. That’s when Eric Offermann of Laserthing.com stepped in. With a laser cutting business in Manassas, VA, and the heart to do whatever it takes to save lives on the frontlines, he and his sister, Karen, started to cut and donate all of the polyethylene(PETG) sheets they had on hand. Eric is at the center of the Nova Labs PPE efforts and an integral part of the leadership team. When supplies of PETG ran out nationwide, Eric helped secure a donation of 154 imperfect sheets from Polymershapes in Jessup, MD, and continued to deliver cut shields to the assembly teams so Nova Labs could keep providing PPE to hospitals and first responders in the area.

As soon as the media started covering the impending PPE shortage, the makers at NOVA Labs got to work. With the physical Nova Labs facility closed, the team resorted to trying to cut shield material by hand. That’s when Eric Offermann of Laserthing.com stepped in. With a laser cutting business in Manassas, VA, and the heart to do whatever it takes to save lives on the frontlines, he and his sister, Karen, started to cut and donate all of the polyethylene(PETG) sheets they had on hand. Eric is at the center of the Nova Labs PPE efforts and an integral part of the leadership team. When supplies of PETG ran out nationwide, Eric helped secure a donation of 154 imperfect sheets from Polymershapes in Jessup, MD, and continued to deliver cut shields to the assembly teams so Nova Labs could keep providing PPE to hospitals and first responders in the area.

Brad Hess and the crew over at Makersmiths have also made a tremendous contribution. From help with lasercutting, to building templates for the Airway Procedure Tent, to sharing resources, having another makerspace as a partner in getting the job done has been priceless. Makersmiths is also independently making and supplying PPE.

Brad Hess and the crew over at Makersmiths have also made a tremendous contribution. From help with lasercutting, to building templates for the Airway Procedure Tent, to sharing resources, having another makerspace as a partner in getting the job done has been priceless. Makersmiths is also independently making and supplying PPE.

Makers at NOVA Labs have run into many of the same challenges facing the national and global PPE shortages, such as issues in the supply chain and shortages of necessary materials to produce PPE, including the PETG sheets needed for face shields.

To overcome these obstacles, makers have had to get creative and source unconventional supplies. When not a single distributor across the entire country could provide the material needed, Polymershapes came to the rescue with a pallet of imperfect PETG sheets that were perfect for making face shields. Knowing that Nova Labs is donating all the PPE they are making, and often the makers themselves are paying for materials out of pocket, Polymershapes donated enough PETG to make over 7,000 more shields.

With the help of these generous partners, and a huge community of volunteers well beyond Nova Labs members, this community has printed thousands of custom headbands, attached the shields, and delivered them to hospitals and first responders throughout the D.C., Virginia, and Maryland area, including the Veterans Affairs Hospital in Washington, D.C., and shipped donations to facilities in need from North Carolina up to New York and Michigan.

Members from Veterans Association Medical Center receiving face shields, courtesy of NOVA Labs.

Support Nova Labs PPE Production

The resourceful, self-motivated group that is NOVA Labs has provided invaluable help for the healthcare workers fighting COVID-19. With their intelligent solutions, dedication, and charity, they have helped protect many of our essential healthcare workers.

In addition to developing 3D products and unique solutions to problems posed by COVID-19, instilling a sense of community is perhaps one of Nova Labs greatest accomplishments, alongside being a successful PPE equipment supplier. By building a space where makers of all ages and backgrounds can meet and collaborate, NOVA Labs presence will be felt and appreciated for many years to come by the individuals it welcomes, and the frontline responders using the end products of this inspiring makerspace.

Support the heroic effort to protect healthcare workers by donating directly at Nova Labs PPE Fund. Contributions will be used to cover material costs so Nova Labs can continue to produce and supply PPE.

Source: NOVALabs.com